How is Fertilizer Produced?

The basic process of fertilizer production:

1. Collection and treatment of raw materials:

The collection and treatment of raw materials for fertilizer is an indispensable part of agricultural production.The main raw materials of fertilizer include nitrogen, phosphorus, potassium and other elements. The collection and treatment of these elements are essential for the development of agricultural production.

In terms of collection, the main raw material for nitrogen fertilizer is nitrogen in the air, while the raw materials for phosphate fertilizer and potash fertilizer mainly come from minerals and ores.The collection of these raw materials requires professional exploration and mining, as well as environmental protection and rational use of resources.

In terms of processing, the raw materials of fertilizer need to go through multiple steps of processing and processing to become the final fertilizer product.These steps include physical treatment, chemical treatment, biological treatment, etc., of which chemical treatment is the most important step.In the chemical treatment process, multiple links such as reaction, separation, and purification are required to ensure the quality and stability of fertilizer.

At the same time, in the process of collecting and processing raw materials for fertilizer, it is also necessary to pay attention to environmental protection and rational use of resources.Pollutants such as wastewater and exhaust gases generated during the collection and treatment process need to be treated and discharged to reduce their impact on the environment.In addition, it is also necessary to make rational use of resources to ensure the sustainable supply of fertilizer raw materials.

2. Reactor selection and design:

When choosing a fertilizer reactor, a variety of factors need to be considered, such as reactant properties, reaction conditions, reaction rate, etc.At the same time, when designing the reactor, it is also necessary to consider the size, shape, material and other factors of the reactor.

First of all, the nature of the reactant needs to be considered when choosing a reactor.For example, if the reactant is highly corrosive, it is necessary to choose a material with better corrosion resistance.In addition, the viscosity, density and other physical properties of the reactant will also affect the choice of reactor.

Secondly, the reaction conditions are also an important factor in the selection of the reactor.For example, when the reactor needs to withstand high temperature and high pressure conditions, it is necessary to choose a reactor that can withstand these conditions.At the same time, the sealing performance of the reactor also needs to be considered to ensure that no leakage will occur during the reaction.

In addition to selecting reactors, designing reactors is also a part of fertilizer production that cannot be ignored.The size, shape, material and other factors of the reactor will affect the efficiency of the reaction and the quality of the product.For example, the larger the volume of the reactor, the higher the reaction efficiency, but the cost will increase accordingly.In addition, the shape of the reactor will also affect the rate and uniformity of the reaction.

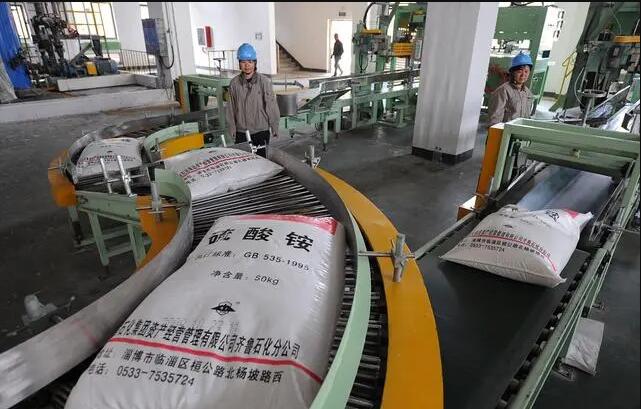

3. Processing and packaging of fertilizer:

In the process of fertilizer processing, multiple processes are required, including the screening, grinding, mixing, and matching of raw materials.In this process, various advanced equipment and technologies need to be used to ensure the quality and stability of fertilizer.At the same time, factors such as temperature, humidity and atmosphere need to be strictly controlled during the processing process to ensure that the composition and properties of fertilizers meet the standards.

In terms of fertilizer packaging, professional technology and equipment are also required.There are many packaging methods for fertilizers, including bagged, bulk, barreled, etc.Among them, bagging is the most common way.In the process of bagging fertilizer, automated packaging machinery needs to be used to improve packaging efficiency and reduce labor costs.In addition, strict quality inspection of packaging bags is required to ensure the quality and safety of fertilizer packaging.